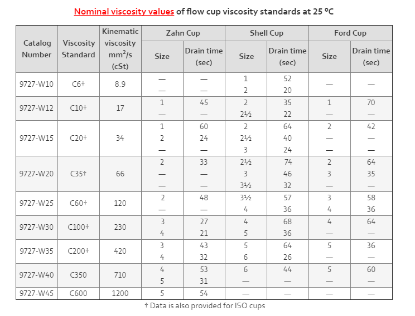

The Cannon Instruments C200 Viscosity Standard is a high-volume calibration fluid designed for precise and consistent viscosity measurements using Zahn, Shell, and Ford flow cups. This standard includes detailed, lot-specific kinematic viscosity data in mm²/s (cSt), as well as calculated cup drain times. Ideal for high-throughput environments, it delivers exceptional accuracy at nominal temperatures of 25 °C, with additional reference data at 20 °C and 23 °C to meet demanding laboratory and industrial quality control needs.

Product Features

- Viscosity Standard: C200, suitable for flow cup calibration applications

- Standard Size: 5 Gallon (18.9 L) bulk volume for large-scale usage

- Includes lot-specific kinematic viscosity data in mm²/s (cSt)

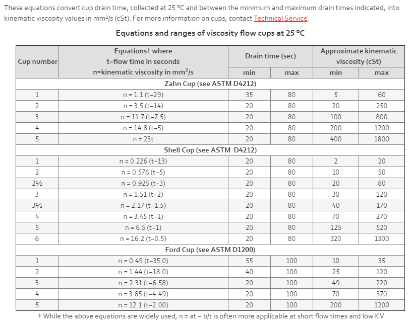

- Calculated drain times for Zahn, Shell, and Ford flow cups provided

- Data available at 25 °C, with supplementary values at 20 °C and 23 °C

- Complies with ASTM D4212 and ASTM D1200 standards for viscosity testing in Australia

- Ideal for laboratories and production facilities requiring bulk calibration standards

Benefits

- Ensures precise calibration of flow cups for consistent viscosity measurements

- Supports traceability and compliance with industry standards through lot-specific data

- Bulk 5-gallon format reduces cost per test and ensures supply for extended operations

- High reliability for both routine and critical viscosity checks

Why Choose Cannon Instruments C200 Viscosity Standard?

Cannon Instruments is a globally trusted name in viscosity measurement solutions. The C200 Viscosity Standard offers large-scale laboratories and industrial operations an accurate, ASTM-compliant calibration solution. With comprehensive data and proven reliability, it helps maintain precision and quality assurance in viscosity-dependent processes. When consistency, compliance, and capacity matter, Cannon Instruments delivers unmatched performance and value.