Smaller refrigeration systems usually have a piston compressor. Piston compressors are positive displacement machines. These differ in their characteristics decisively from flow equipment which include the turbo compressors that are common in very large systems.

In piston compressors the flow rate is mainly dependent on the displaced volume and speed. Due to the unavoidable dead space the flow rate drops with increasing pressure ratio. Because the flow rate is a measure for the refrigeration capacity of the refrigeration system, the properties of the compressor are important for the capacity of the whole system.

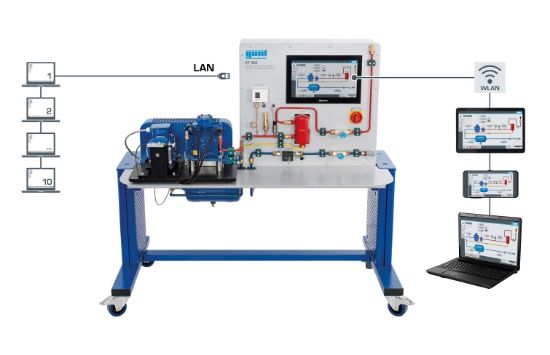

In ET 432 a commercial open refrigerant compressor is operated in an open process with air. The inlet and outlet pressures and thus the pressure ratio can be adjusted via valves in wide ranges. The drive via a frequency converter permits variable speeds. Pressures, temperatures, electric power consumption, speed and torque are recorded.

The trainer is controlled by the PLC via touch screen. By means of an integrated router, the trainer can alternatively be operated and controlled via an end device. The user interface can also be displayed on additional end devices (screen mirroring). Via the PLC, the measured values can be stored internally. Access to stored measured values is possible from end devices via WLAN with integrated router/LAN connection to the customer’s own network. Via direct LAN connection the measured values the measured values can be transferred to a PC and stored there (e.g. via MS Excel).