ASTM Approves A New Automated Procedure D for D2983

The TESC-2983 is a fully-integrated thermoelectrically heated-cooled sample conditioner and rotational viscometer system that offers vastly improved precision (nearly 2 times better) with Procedure D over the other manual D2983 procedures. The system offers limited operator intervention compared to the other labor-intensive procedures. The TESC-2983 is a cost effective, ultra-compact design with low energy consumption (only 300 W power). Its small footprint conserves bench space and allows installation of multiple TESC systems providing redundancy and multiple temperature cycles. The Peltier solid-state cooling is environmentally friendly and does not require the use of hazardous CFC refrigerants or flammable bath fluids. The enclosed insulated sample chamber mitigates the effects of laboratory air temperature on the test. The TESC-2983 has pre-programmed test protocols for common lubricants (gear oil and automatic transmission fluids) which reduces instrument set-up time. The unit also measures and records viscosity at multiple speeds automatically. The easy-lift system of the TESC simplifies positioning of the viscometer head.

For Low Temperature Viscosity of LubricantsAutomated

ASTM D2983

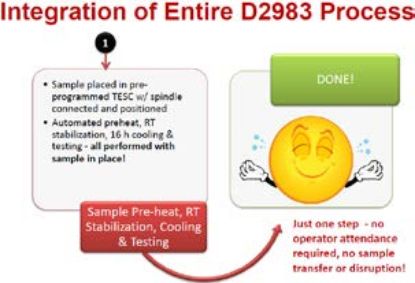

The compact, economical TESC-2983 (thermoelectric sample conditioner) viscometer system provides outstanding precision for the new ASTM D2983 automated procedure D conditioning and testing process for low temperature viscosity of gear oils and ATF, as well as ASTM D8210. Allows for unattended operation. Environmentally-friendly Peltier thermoelectric cooling does not require hazardous fluids. Eliminates sample disruption during preheating, room temperature stabilization, cooling and final viscosity testing. Reduces result variability due to temperature fluctuation. Provides superior precision.

Common Applications

- Gear oils

- Automatic transmission fluids

- Torque and tractor fluids

- Industrial and automotive hydraulic oils

- Industrial lubricants

- Other fluids where low-temperature viscosity is critical

Features & Benefits

Fully integrated and automated thermal conditioning and testing (−40 °C to +90 °C)

- Provides an automated alternative to ASTM D2983 sample conditioning and testing

- Eliminates sample disruption during preheating, room temperature stabilization, cooling and final viscosity testing

- Reduces result variability due to temperature fluctuation

- Provides superior precision

- Allows for unattended operation

Pre-developed test programs for common lubricants (gear oil and ATF)

- Reduce instrument set-up time

- Measure viscosity at multiple speeds automatically

Cost effective, ultra-compact design

- Allows installation of multiple TESC Systems in a relatively small benchtop area for redundancy and greater testing versatility

- Conserves precious bench space

- Dedicated PC is not required for standard instrument operation*

Easy-lift system

- Configured for use with the Brookfield® DV2T viscometer and compatible with most Brookfield® models

- Simplifies positioning of the viscometer head

Solid-state thermoelectric cooling

- Eliminates need for flammable bath fluids to improve safety

- Enclosed sample chamber mitigates the effects of laboratory air temperature on the sample

Digital recording, printing and exporting of thermal test history and final viscosity data for convenient import into Microsoft® Excel® or other programs

* A PC is required to reprogram the unit for tests other than gear oil at 40° C

Ordering

Thermoelectric Sample Conditioner (TESC) System consists of the thermoelectric sample conditioner unit, Brookfield® DV2T viscometer, temperature control software, #4B2 spindle, EZ-Lock spindle coupling, pre-loaded test programs on USB memory stick, USB to RS-485 cable, test cells (12 pack), 20 mL plastic syringes (5 each), CL160 viscosity reference standard (500 mL) and Rheocalc software. The unit is pre-calibrated for testing gear oil at −40 °C. Specify desired factory installed options when ordering. A computer is note required for normal operation but is required if reprogramming instrument test parameters.

Alternative sample/temperature calibration (other than gear oil at −40 °C) is available at the time ordering.