Compressed air for industry and businesses that use compressed air as an energy source is generated by means of so-called compressed air generation systems. A key component of these systems is the compressor. It converts the supplied mechanical energy into a higher air pressure. Such systems are used to drive machines in mining, for pneumatic control systems in assembly plants or tyre inflation systems at petrol stations.

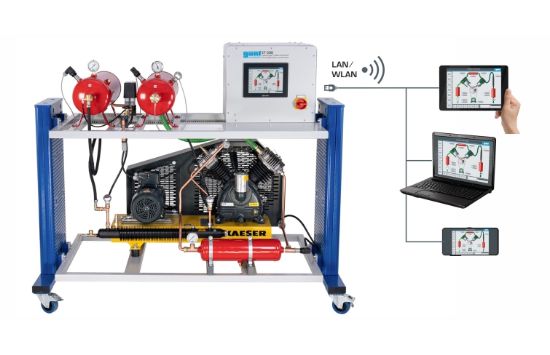

ET 500 includes a complete compressed air generation system with a two-stage compressor and an additional pressure vessel as intercooler. The trainer enables the recording of compressor characteristics and representing the compression process in a p-V diagram.

The air is sucked into the intake vessel through a measuring nozzle and calmed there before it is compressed in two stages. The additional pressure vessel for intercooling is located between the first and second stage. After the second stage, the compressed air is pressed into another pressure vessel through a cooling tube. To achieve a steady state, the compressed air can be released through a blow-off valve with silencer. Safety valves and a pressure switch complete the system.

Sensors measure the pressures and temperatures in both stages as well as the electric power consumption. A nozzle at the intake vessel serves to determine the intake volumetric flow rate. The experimental unit is operated via a touch screen with intuitive user interface. By means of an integrated router, the experimental unit can additionally be operated and controlled via one end device and the user interface can be displayed on up to 10 end devices (screen mirroring). Via the PLC, the measured values can be stored internally. Access to stored measured values is possible from end devices via WLAN with integrated router/ LAN connection to the customer’s own network.